The regulation of nuclear cogeneration

Introduction

The current regulatory landscape for civil nuclear power plant in many counties is predicated on the generation of electricity. Future use of nuclear derived energy will support many well reported non-electric applications. Using nuclear-generated steam for multiple purposes maximises the utilisation of the reactor and has the potential to keep energy demand stable, even when electricity needs are low. Cogeneration is not new, and many good practices already exist (e.g., the use of hot water in district heating). This report examines the evolving regulatory landscape in response to the shift in nuclear energy use, highlighting key changes, emerging challenges, and potential opportunities. It does this by looking at the regulation of nuclear cogeneration at four levels – engineering, plant, downstream (end) user and regulatory.

Engineering level

General engineering principles important for the safe, secure, and environmentally friendly management of the risks associated with nuclear cogeneration are reported in the literature [1] [2] [3] [4].

These include

Integrated safety and control. Analysis of safety, security, and environmental impact should take account of the interaction of the reactor and any cogeneration facility in normal operations and any fault conditions. The transient capabilities of the nuclear reactor under normal or accidental conditions should match the transient loads imposed by the industrial processes. A common control strategy is needed for both facilities. For example, if a significant proportion of the reactor energy is directed to a downstream user for co-generation, a sudden trip of the cogeneration plant would result in the reactor needing to dump capability or divert the energy to interim storage. Failure to do this could result in plant degradation and criticality control complications. Buffer capacities can help smooth these transients.

Industrial hazards. The nuclear safety case must address risks from nearby industrial facilities including any explosive or toxic material from industrial chemical processes (e.g. explosion – hydrogen and toxic gas - sulphur dioxide, sulphur trioxide and sulphuric acid).

Contamination and isolation. Systems should be implemented to prevent radioactivity migration and avoid cross contamination between the nuclear site area (i.e. the geographical area that contains an authorised facility) and downstream industrial processes. This should include preventing corrosive chemicals and contaminants from entering the reactor system from the industrial processes. A single failure of one system should not weaken the safety of another. Mechanical barriers and pressure differences should be used across heat exchangers to ensure transport of radioactive substances (e.g. tritium) is minimised off the nuclear site area. The export of the energy should be in a form of a closed loop system to maintain cooling balance.

Operations. Nuclear power plant operations should provide backup heat or power sources in case either plant stops operating (e.g. for refuelling and maintenance). Priority should always be given to the nuclear power plant with immediate transition from cogeneration to stand-alone electrical operation without tripping the nuclear reactor.

Emergency preparedness. Emergency response should include the need for detailed plans for public notification, sheltering or evacuation in the event of an accident. Ensure public education and programmes are available to maintain public awareness.

Plant level

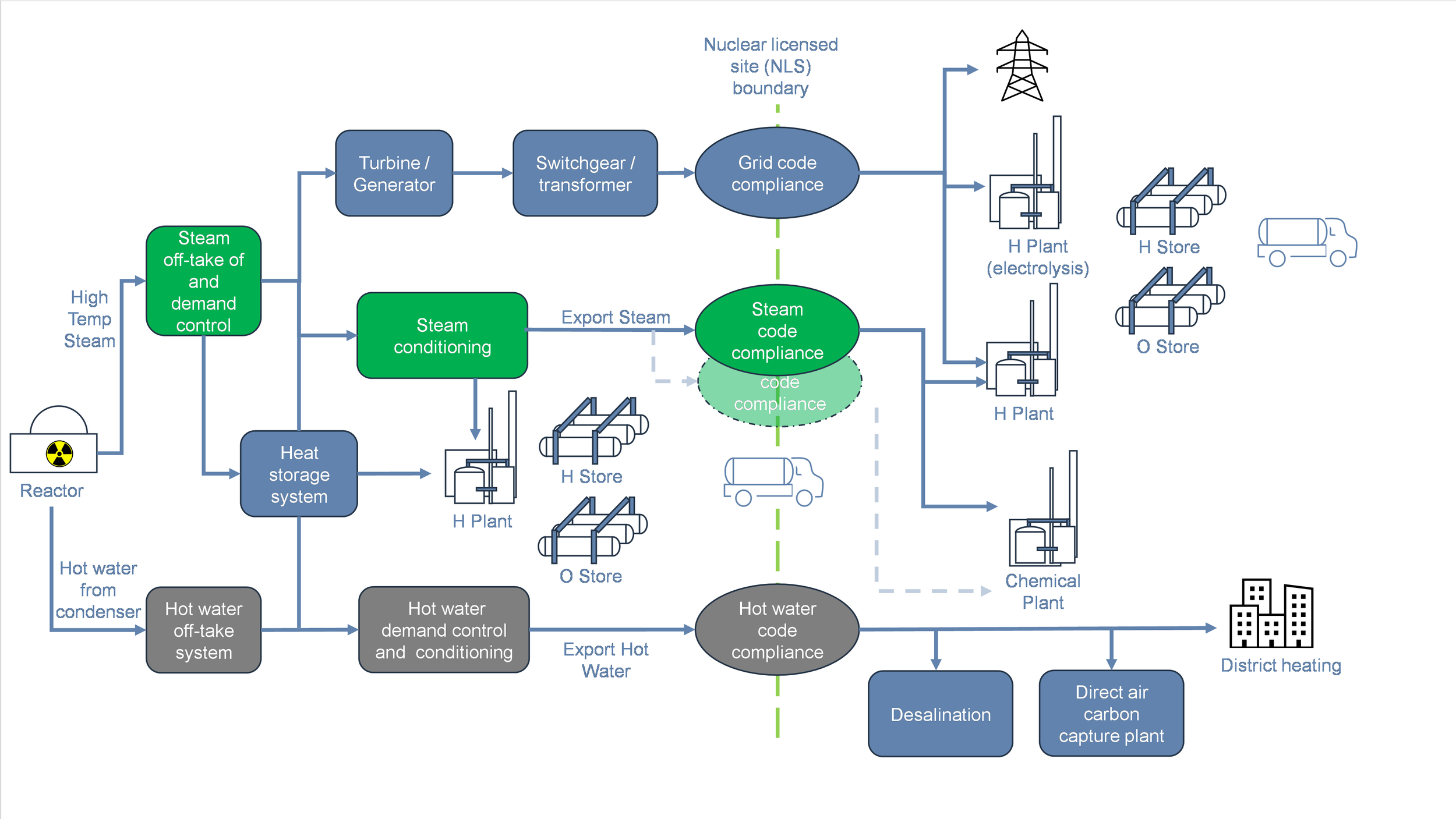

A systems view of the engineered components and energy system arrangements associated with nuclear cogeneration has been developed and is shown in the figure below.

In the figure above the dashed vertical green line | represents the limit of the nuclear site area. The reactor is treated as a black box which produces.

high temperature energy (e.g. steam) for electricity generation and to support energy-intensive industries represented as chemical and hydrogen (H) plants, and

low temperature energy (e.g. hot water / lower temperature steam from the condenser) which can be used for applications such as.

district heating [5].

desalination [1].

direct air carbon capture plant – e.g. capturing carbon dioxide by passing air over chemicals to remove the carbon dioxide and “regenerate” the chemicals for further operations.

In addition, heat could be stored in a medium to provide a buffer to cogeneration applications.

It is argued that a number of plant systems are needed in order to satisfy the likely engineering level regulatory expectations. These are similar in principle with those readily used for the generation of electricity (e.g. arrangements for the export of electricity on to a grid including technical requirements and commercial arrangements) and in non-nuclear combined heat and power plants [6]. Considerations for the requirements of these systems are included in Annex A.

Cogeneration plants may be located on-site or off-site. In practice siting of cogeneration plant is influenced by multiple drivers with varying impact levels including those listed in the table below.

Factors that may drive the cogeneration plant on-site

Reactor Proximity - minimise steam energy losses by reducing transmission distance.

System Integration - boosts efficiency but heightens operational interdependence.

Licensee Oversight - Greater licensee control over reactor-related systems and cogeneration plant. Ensures oversight is provided by nuclear competent organisation.

Cooling & Contamination Management - Localises chemical and radiological risks, preventing offsite impact and backflow hazards.

Factors that may drive the cogeneration plant off-site

Hazardous material storage – Minimise hazards near sensitive nuclear infrastructure.

Operational isolation - Separates nuclear and chemical processes and isolates the nuclear reactor from hydrogen plant transients.

Complexity & cost – Cogeneration plant needs to comply with nuclear license conditions which adds regulatory scope and associated burden.

Downstream (end) user level

Nuclear cogeneration is likely to introduce greater operational complexity compared to the dedicated use of nuclear energy for the generation of electricity. This is due to factors such as:

• Seasonality. For example, changing demands associated with district heating and solar energy production.

• Diversity in the use of nuclear derived energy. For example, electricity, chemical processing, and hydrogen production.

• Variety in contractual arrangements in place for the use of the energy.

• Shift from centralised generation sources towards more dispersed energy generation making the balance of supply and demand on the grid more complex.

In many countries generated electricity is sold into a marketplace. These factors are likely to result in an increased marketplace complexity for nuclear energy. Instead of nuclear being used exclusively for electricity generation and national electricity grid stability, nuclear licensees will be subject to complex marketplace drivers. This increase in the dynamic nature of the nuclear derived energy use is likely to increase the commercial motivations that could impact on nuclear power plant operations and therefore nuclear safety, security, and environmental protection.

The increased complexity and interconnectedness of nuclear energy use requires the need for coordination between the nuclear licensee, downstream users of high temperature steam and hot water and other market operators.

Regulatory level

Some regulatory frameworks have not had to consider regulatory arrangements for non-electric application of nuclear. This lack of regulatory arrangement is considered to be a potential gap and there may be an opportunity to consider this further within regulators remit to promote an efficient, coordinated, and economical electricity and gas system.

It is helpful to consider the overlay of current regulatory jurisdiction of relevant regulatory bodies and the role of each regulator. It may be that currently the regulatory coverage is sufficient to cover all activities within the whole cogeneration system. However, there is a potential for a gap in arrangements between key regulators which may need to be addressed to ensure effective cooperation and coordination of regulatory activity (e.g. seamless regulation on and off the nuclear site area). Regulatory cooperation will be necessary across the life cycle of a nuclear site.

Summary

A whole system model of nuclear cogeneration has been considered.

At an engineering Level

A whole-system view has identified additional systems needed for nuclear cogeneration.

These additional systems are similar to existing reactor and combined heat and power facilities. However, they may have not been considered / demonstrated for nuclear cogeneration.

The level of engineering and supporting arrangements is dependent on the proportion of the energy that is going outside the licensee's control.

Extensive experience exists from nuclear district heating applications.

At a plant design level

Siting cogeneration facilities on nuclear licensed sites has pros and cons.

On-site placement is more efficient and allows greater licensee control.

Off-site placement reduces the risk associated with the storage of bulk hydrogen and reduces nuclear plant complexity and costs.

At a downstream (end) user level

Multiple downstream applications introduce stakeholder complexity.

Stakeholders must collaborate with nuclear licensee to allow them to meet their legal duties and maintain safety, security, safeguards, and environmental protection. This may require the development of new regulatory duties.

At a regulatory level

Greater coordination may be needed due to nuclear-downstream interdependence including:

Oversight of exported energy.

Regulator cooperation on downstream operations and radioactive transfers.

Market arrangements that support nuclear safety and environmental goals.

Ennuvo is grateful to the many experts interviewed as part of this work (chemistry and process engineering, electrical engineering, environment and advanced nuclear technologies, hydrogen distribution safety, nuclear reactor operators, energy systems economist).

References

[1] “Nuclear cogeneration: civil nuclear energy in a low-carbon future.,” The Royal Society, London, 2020.

[2] “Combined heat and power - technologies. A detailed guide for CHP developers – Part 2.,” Department for Business Energy and Industrial Strategy, London, 2021.

[3] “Nuclear Heat Applications: Design aspects and operating experience.,” International Atomic Energy Agency., Vienna, 1998.

[4] “Opportunities for Cogeneration with Nuclear Energy,” International Atomic Energy Agency, Vienna, 2017.

[5] “Guidance on Nuclear Energy Cogeneration.,” International Atomic Energy Agency, Vienna, 2019.

[6] “HTGR Industrial Application Functional and Operational Requirements.,” Idaho National Laboratory, Idaho Falls, 2010.

[7] “Next generation nuclear plant phenomena identification and rank tables (PIRTs). Volume 6: Process heat and hydrogen co-generation PIRTs,” Office of Nuclear Regulation Research, Oak Ridge, TN, 2007.

Annex A - Systems and arrangements for the export of high and low temperature energy

High temperature off-take and demand control

This system(s) enables the transfer of steam for multiple applications allowing the energy generated and used to be balanced. Many of the design features (e.g. engineered components and procedures) are similar to existing reactor operations and combined heat and power facilities [6]. However, they may have not been considered / demonstrated for nuclear cogeneration [1]. Considerations include:

Managing thermal transients due to changes in heat demand (e.g. from downstream users).

Capability for full load rejection of steam following a loss of demand to maintain reactor cooling.

Separation between the reactor and downstream users so that downstream use can be conventionally designed and repaired.

High temperature conditioning systems

This system(s) ensures the exported energy is in a form that is compliant with end user specifications [2] [6]. Considerations include:

Designed to minimise the transfer of radioactive materials off-site (e.g. tritium) and avoid any long-term contamination (e.g. multiple intermediate loops, barrier systems and pressure differentials).

Monitoring each loop for contamination (e.g. conductivity, pH, tritium).

Ensuring the export and return legs are “compliant” with defined characteristics (e.g. pressure, temperature, safe capacity, pH, conductivity, presence of organic contaminants & oxygen).

Provide shutoff valves along intermediate loops to isolate the nuclear or chemical plant from any accidental rupture detected in the loop.

High temperature compliance arrangements

Arrangements and agreements for the technical and, if necessary, commercial stewardship of the exported energy. There may be a need to have more than one agreement if there are multiple users of the energy.

Stakeholders could include nuclear licensee, downstream user(s), other supply chain representatives, legal / financial stakeholders, government entities, and regulators.

Agreements may include availability of steam, supply / demand profiles (daily, weekly, seasonal), arrangements for maintenance and dealing with fault conditions, penalties, payment terms, and termination.

Develop shared competency and establish the necessary culture to ensure safe, secure, and environmentally friendly operation of the nuclear facility and any downstream user.

Low temperature off-take and demand control

The cooling provided by the exported energy should be known and have little impact on the reactor primary circuits. Design precautions should consider transients, partial loads, means of preventing faults and the propagation of faults between components, and ensuring appropriate protection and mitigation of accidents if prevention fails.

Low temperature conditioning systems

Good practice based on experience includes:

At least two mechanical barriers (e.g. heat exchangers) between the nuclear reactor primary loop and the export of the energy off the nuclear site.

Export of the energy is in the form of a closed loop system to maintain reactor cooling balance and minimise the potential for inflow of contaminants.

Use pressure reversal differences across heat exchangers to ensure radioactive ingress (e.g. tritium) into the media being exported off the site area remains below that specified in regulatory limits.

Have at least one mechanical barrier (e.g. heat exchanger) between the export heat loop and consumers to allow isolation of the exported heat and prevent ingress of contamination upstream.

Low temperature compliance arrangements

Undertake routine monitoring of operational parameters to ensure safety, environmental and contractual requirements are maintained within agreed regulatory limits (e.g. radioactive / chemical contamination, inlet and outlet temperatures and pressures in circuits, pressure and temperature differences in heat exchangers).

Arrangements are in place to ensure any shared asset (e.g. heat loops) are maintained effectively.

Provide a means for locating and detecting faults and implementing timely repairs.

For desalination ensure isolation effectiveness results in compliance with national and international drinking water standards.